TQSOFT

Data Processing for Sterilisation Processes Version 9

CONTENTS

Data Processing for Sterilisation Processes Version 9

Computer and Operating System Specification.

1.2 Using the TQSoft Interface

2.0 Company Name and General Settings

2.1 Security and Electronic Signatures

2.1.3 Changing and reminding Passwords

2.1.4 To De-Activate an Operator

2.1.5 To Change what an Operator can Do

2.1.6 To Backup or Move All Operators to another Computer

2.1.7 Adding Digital Signature to Records

2.1.8 Adding Electronic Signatures

2.3.1 Identifying Channels for Analysis and TQEXPRESS.

2.5.4 Manual Calibration Adjust

2.5.6 Advanced Calibration for Remote Loggers.

2.5.6.1 Manual Setpoint Calibration Procedure

2.5.5 Calibration Measurement Adjustments

2.6.4 Selecting which Probes to log and probe Groups

2.6.5 Setting up a Stage List for a Test Specification.

2.6.6.1 Introduction & I-Calc Wizard

2.6.6.4 Deciding Which Type of I-calc to Use

2.6.6.6 The EN554 Demonstration

2.6.6.7 Stage Names, Intervals and Special Codes.

2.6.6.8 Editing Groups of I-Calcs.

2.6.7 Logger Specific Specifications

2.6.9 Creating a new Test Specification

2.7 Temperature Reference Setup and Control

2.8 Thermal Bath Setup and Control

2.9.1 Adding Equipment to a Chamber

2.9.2 Adding Reports for a Chamber (System Accuracy

Test)

2.10 The Test Equipment Database

2.10.1 The Logger Correction Factor

2.11.1 Custom Stages and Special Stages

2.12 The 3D Sensor Positions

Diagram

2.12.2 The Positions Control Panel

2.12.3 Putting the 3D Diagram into

Reports

3.3 Starting a Test (Using the GO button)

3.4 Do’s and don’ts while a Test is being logged.

3.5.1 The Inputs Display Drop Down Menu

3.5.3 Stability and Fluctuation Monitoring

3.6 Using the real time Chart.

3.7 Viewing real time Data Listing.

3.8 If a Channel goes Full Range.

3.8 Entering Stages as they happen.

3.9 The ‘View’ Button. Looking at Historical Tests while logging.

Diagram: TQSoft Calibration Checking Automatic File Management.

4. Accessing Tests and Calibration Records Historically

4.2.1 Configuring the Historical Test Index

4.2.2 Configuring the Historical Test Index for Hierarchical Tree view

mode.

4.3.2 Setting Up Stages using the Chart.

4.3.4 Displaying a Shaded Area on the Chart.

4.4.1 Data Listing Configuration

4.4.2 Producing a Data Listing Summary with Stages

4.4.3 The Data Listing Printout

4.6 The Historic Channel Configuration

4.7 Calibration Records Viewing Signing and Printing.

4.7.1 Adding Electronic Signatures to Reports

4.8 Calibration Report for each Test.

4.9 Calibration Checking Records Viewing and Printing.

4.10 Calibration Checking Report for each Test.

4.11 Making a Systems Accuracy Test from the Chart

4.12.3 Data Management

Specification Table.

File Synchronization Omission List

Audit Trail Specification (RS1_6)

5.1 The Audit Archiving Function

5.2 Maintaining the Audit Trail

5.3 Archiving and Viewing an archived Audit Trail

Appendix B Fluke Hydra Connection

Appendix C Kaye Equipment Setup Notes

Appendix D Kaye DigiStrip, KL, Portable with TQSoft Notes

Note 1 Configuation and Validation Scheme

Note 2 Channel Configuration Details

Kaye Calibration Considerations

Appendix D2 Kaye Validator 2000 Notes.

Appendix E Eurotherm 4250M Recorder

Appendix F Anville Series 400 Loggers

Appendix G Using Channels other that Temperature and Pressure e.g. Humidity.

Appendix H The Simulation Logger

Appendix I The

KeySight/Agilent Loggers

How to use the Loggers

Remote from TQSoft with USB

How to use the Loggers

Remote from TQSoft with Memory

Appendix J Independent

Chamber Monitoring Features Overview.

Special Configuration for

Automatic Mode

Digital Input Required

for Automatic Test Start and Stop

Automatic Process

Recognition on Multi Process Chamber

Automatic Complete Test

Analysis

Appendix K Continuous

Monitoring Features Overview

Logged Files can now

cover many Days

New Test Specification

Controls for Continuous Monitoring

Limits and Fail Actions

for Continuous Monitoring

Inserting Stages

Automatically at a certain Time

Appendix L Calibrating Pressure and other non temperature channels.

General Operational Considerations

Setting up a Basic Test Specification

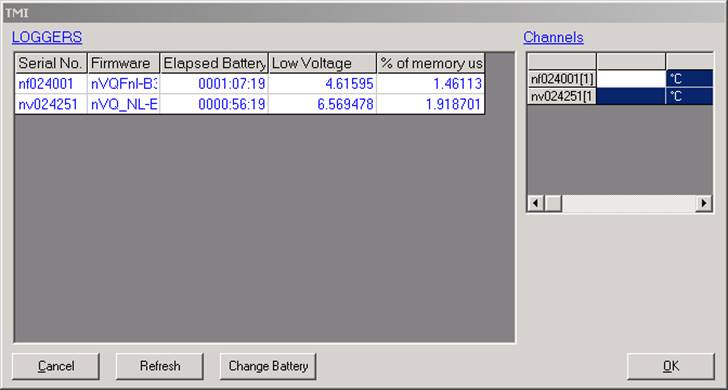

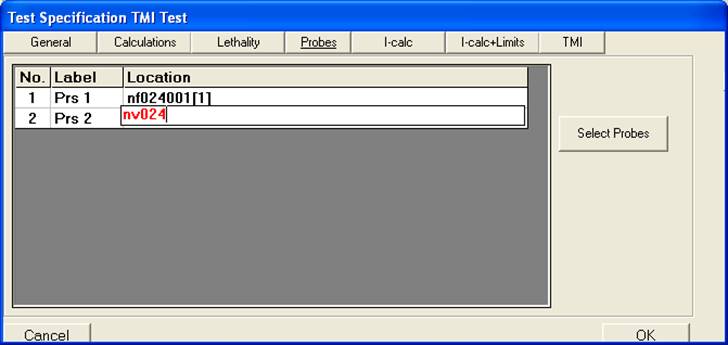

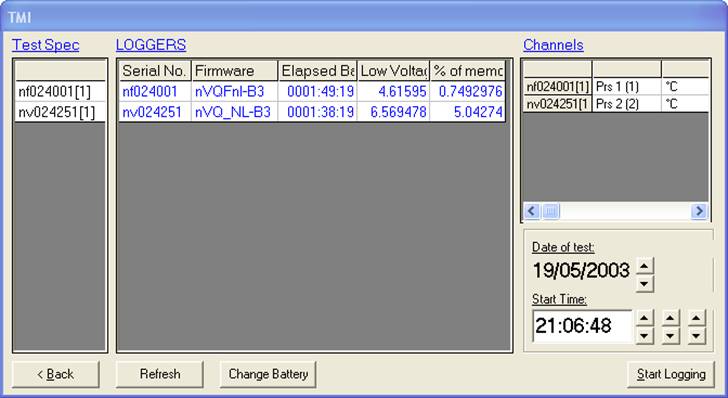

Part 2 Type 2 Loggers NanoVacq, PicoVacq, MiniVacq etc.

General Operational Considerations

Setting up Channel Configuration and

Test Specification for TMI Loggers.

Appendix N Simulating a Test for Validation and Demo.

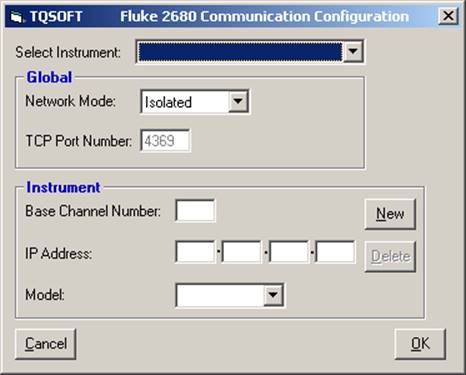

Appendix O Fluke 2680 and NetDAQ Operations

NetDAQ Scan Speed Setting Adjustment

Appendix P Eurotherm 5000/6000 Series units

Appendix Q TecnoSoft Interface

Using Test Specifications with TecnoSoft

Procedure for Forcing data from a specific Logger into a specific Channel

Number.

Synchronizing Scans in TQS-NET

Appendix S Yokogawa DX2000/1000/DX200P/DX100P

Computer Communications Settings

TQSoft Communications Settings

Yokogawa DX Logger Control Window in TQSoft

Channel Configuration Settings

TecnoSoft, MadgeTech and Gemini USB Interfaces

Appendix U Yokogawa DR130/DR23X/DR24X

Computer Communications Settings

TQSoft Communications Settings

Yokogawa DR Logger Control Window in TQSoft

Channel Configuration Settings

Appendix V Grant Squirrel 2040

1. Why Use TQSOFT?

TQSoft is intended for use by professionals involved in thermal validation of steam, fluid and dry heat sterilization processes in pharmaceutical applications, hospitals and healthcare industries.

It is also intended for validation of high quality metal heat treatment furnaces, as well as ovens and fridges and freezers in the food, pharmaceutical , and healthcare industries.

It has fully automatic calibration, test monitoring, data logging, reporting and archiving functionality built around communications interfaces with most of the leading loggers, thermal calibrators and temperature reference equipment.

It has a comprehensive validation plan available, originating from a detailed requirements and functional specification, linking to an acceptance test document covering every aspect of its functionality.

It meets every aspect of 21CFR Part11 and AMS2750 covering requirements and guidelines for electronic records in detail and substance.

It goes beyond these basics by providing a friendly and flexible user interface, detailed, flexible calibration and test reports, as well as an interface to a reporting package (TQEXPRESS) that allows reports to be customized, managed and compiled to PDF format.

TQSoft is unique in that it is an application designed specifically for validation professionals, with many years of input by those very professionals, independent of any particular hardware product vendor.

Computer and Operating System Specification.

This Manual and these specifications apply to TQSoft version 9.x.x. Where x refers to any incremental version.

|

Criteria |

Specification |

|

|

|

|

CPU Processor |

Intel Pentium II or higher |

|

CPU Clock Speed |

600 MHz or higher |

|

CPU RAM |

128 MB or higher |

|

Operating System |

Windows 11 or earlier. |

|

Communication Ports for Logger |

One unused serial port, or USB port with USB to serial Keyspan converter. If using Fluke 2680 a network adaptor is required. |

|

Communication Ports for Thermal |

One unused serial port, or USB port with USB to serial Keyspan converter. |

|

Communication Ports for Reference Temperature |

One unused serial port, or USB port with USB to serial Keyspan converter. |

|

USB |

One USB port for license dongle. |

|

Disk Drives |

Standard CD drive for installation. CDRW or Floppy or Network adaptor for backup and storage. |

|

Printer |

Windows printer. |

|

Monitor |

Colour monitor with at least 256 colours |

|

Screen Resolution |

Minimum 800 x 600. |

Getting Started on TQSoft.

See Document TQSOFT INSTALL,QUICK START, VERSION INFORMATION stored in Manuals folder on CD and supplied printed with CD.

1.2 Using the TQSoft Interface

In general the main display windows in TQSoft can be moved and resized to suit user preferences. The preferred settings are saved and restored automatically.

1.2.1 The Main Toolbar

The main toolbar caption shows which configuration file the program is running from. No indication means that it is running from the standard LOGSYS.ini file. This is important for Monitoring systems.

The toolbar can be re-sized as required by dragging edges with mouse. The toolbar can be made small for monitoring systems. In this case the wording will disappear. If program functions are not allowed an operator, the buttons and drop down menu headers do not appear.

The arrow buttons on the lower right of the toolbar will allow tests to be selected quickly sequentially. Using them will change the current test indicator. With the chart displayed, the chart will be automatically updated with the next test selected.

The Reports button on the right will access the TQExpress reports. The down arrow feature on the button can be clicked to access a complete report that is associated with the current test selection shown on the Current Test menu.

The Historic Tests button down arrow feature can be used to switch to tests that have been recently selected.

1.2.3 The Back Panel

The back panel window can be re-sized and minimized and shut at will independently of the toolbar.

Setting TQSOFT Up

2.0 Company Name and General Settings

The company name is used on all report headings. If the license is removed the name will revert to UNLICENSED SOFTWARE.

The System Identifier is used in the audit trail report and more importantly the first two characters of the identifier are used to tag all setup records so that records from several Chambers or engineers can be held on a server logsys directory.

If the first two characters of the System Identifier are changed, TQSoft will sift through all the setup Test Specifications, calibrations, calibration checks, and calibration files, changing the first two characters of the name.

The Store

The Signature at end of Test and Calibration option prompts an automatic add signature window so that operator can add signature to all records generated.

The Add Signature boxes control where signature section will appear in the Data List printout.

The show calibration summary reports for tests option will include an extra summary sheet for calibration and calibration checks showing a summary for each channel. This summary will be useful when calibration is carried out on multiple groups of sensors or sensors of different type (eg thermocouples and pressure transducers)

The show calibration results tables in calibration reports will show a table of reference versus measured value results for each channel in calibration reports, calibration check reports, and in the test setup report.

The show I-Calc setups in Test Setup report will show a separate parameter section for each I-Calc in the Test Setup report.

2.1 Security and Electronic Signatures

After installation TQSoft will start without requiring an ID/Password. In this mode TQSoft will acquire the operators name from the active Windows account. Inactivity timeout should be left off with the “00:00:00” setting, and password length and age limit settings are not applied.

In Windows account mode 21CFRpart11 compliance must be applied to the Windows user accounts.

Windows account mode is operational until ‘Windows account (Demo)’ is de-activated.

It is possible to leave TQSoft in this security mode rather than use TQSoft’s own user ID and password system.

It might be a good idea to skip this section initially until you have become familiar with other parts of the system.

2.1.1 Security Overview

Each system user will require an ID and password to use TQSoft. Persons who may only want to add electronic signatures to documents will also need to be set up as an operator.

The ID is permanent and must not be forgotten. The password effectively allows an ID to be used and inserted into documents, as the legal equivalent of the users written signature. The password can be changed periodically and, if forgotten, be reminded with the co-operation of the system administrator.

ID's and passwords are always stored in encrypted format, and any TQSoft files that contain a users ID are also protected by TQSoft file security functions (see section 4) so that an ID cannot be simply copied and pasted into other files.

The access settings can be configured so that one or more users can be effectively 'system administrator' with responsibility for adding and deleting operators and configuring an operators' access. All 'system administrator' test record and system access manipulation actions are fully audited

It is important to note that the 'system administrator' is not responsible for setting up an operator's ID and password. The ID and password are setup by the operator the first time he or she logs in. This is because it is a 21CFRPART11 requirement that the ID and password are only known by the their owner (and NOT the system administrator).

2.1.2 The Password Window

The password window appears whenever TQSoft is started (except if Windows account (Demo) is active in the operator list), and can be accessed on the Setup menu.

You are required to enter your ID. If you have not logged on to TQSoft before, and you know that the System Administrator has added you to the list of users, you should press the New User button and select your name from the list of new users, then press ENTER and create your ID and password. Your ID could simply be your name alone, or with something extra (rather like a hand-written signature is your name written a special way)

Press ENTER when you have finished on each box. You are then required to enter the date that your password will expire. When a password has expired if you use it to log on then TQSoft automatically asks you to create a new password.

At any point, to go back a step in the password window, simply press the Esc key.

2.1.3 To Add an Operator

From the Setup dropdown menu select Edit Security. Note that this function can be assigned to a single individual, effectively a System Administrator.

Important: Access settings are stored in a file (operat3.ini) in the LOGSYS directory. The passwords are encrypted. If this file is altered in any way using a

text editor, access to TQSoft will be impossible.

Type the new name into the Name box, then press Add to List. The operator will be added to the list. When the new user first logs into TQSoft he or she should press the New User button in the password window, then setup an ID and password.

The new user is auto assigned to the Operator group profile settings. Select a different group with the groups selector for example to make the new user an Admin. Use the Groups tab to modify each group’s default profile. When a group profile is modified, each user that is assigned to the group will have their profile updated.

|

Hardware |

Operator |

Manager |

Admin. |

|

Select type of Logger/Recorder |

|

Yes |

Yes |

|

Select Channel Configuration (Download) |

|

Yes |

Yes |

|

Logger Control |

|

Yes |

Yes |

|

Calibration |

Yes |

Yes |

Yes |

|

Advanced Calibration |

|

Yes |

Yes |

|

Calibration Files Manual Adjust (Edit) |

|

|

Yes |

|

Calibration Files Manual Adjust (Edit) Logger |

|

|

Yes |

|

Calibration Checking (&Validation) |

Yes |

Yes |

Yes |

|

Calibration Files |

|

Yes |

Yes |

|

Thermal Bath |

|

Yes |

Yes |

|

Stability Criteria |

|

Yes |

Yes |

|

Temperature Reference |

|

Yes |

Yes |

|

Setup |

Operator |

Manager |

Admin. |

|

Edit Security |

|

|

Yes |

|

Audit Trail |

|

Yes |

Yes |

|

Company Name and General Setup Options |

|

Yes |

Yes |

|

Test Equipment |

Yes |

Yes |

Yes |

|

Edit Chamber Records |

|

Yes |

Yes |

|

Sensors Position |

|

Yes |

Yes |

|

Edit Channel Configuration |

|

Yes |

Yes |

|

Default Chart Configure |

|

Yes |

Yes |

|

Default Data Listing Configure |

|

Yes |

Yes |

|

View Saturated Steam Tables |

Yes |

Yes |

Yes |

|

Test Specification |

Operator |

Manager |

Admin. |

|

Edit Test Specs |

|

Yes |

Yes |

|

Calculations |

|

Yes |

Yes |

|

Lethality |

|

Yes |

Yes |

|

Stages |

|

Yes |

Yes |

|

I-Calc Specs |

|

Yes |

Yes |

|

I-Calc List |

|

Yes |

Yes |

|

Tests |

Operator |

Manager |

Admin. |

|

Start Logging |

Yes |

Yes |

Yes |

|

Start Logging/ More |

|

Yes |

Yes |

|

Test Audit Trail |

|

Yes |

Yes |

|

Test Setup Report |

Yes |

Yes |

Yes |

|

Test Details |

Yes |

Yes |

Yes |

|

Calibration Records for Test |

Yes |

Yes |

Yes |

|

Edit Channel Configuration |

Yes |

Yes |

Yes |

|

Stages |

Yes |

Yes |

Yes |

|

Stages / Real time |

Yes |

Yes |

Yes |

|

Defective Probes |

|

Yes |

Yes |

|

Charts Display |

Yes |

Yes |

Yes |

|

Data Listing |

Yes |

Yes |

Yes |

|

Test Notes |

Yes |

Yes |

Yes |

|

Export / Import Data |

|

Yes |

Yes |

|

Re-Analysis |

|

Yes |

Yes |

|

I-Calc and Limit Report |

|

Yes |

Yes |

|

Crop Data |

|

|

Yes |

|

Historic Tests |

Yes |

Yes |

Yes |

|

Historic Tests / Configure |

Yes |

Yes |

Yes |

|

Data file management |

|

Yes |

Yes |

|

Archiving |

|

Yes |

Yes |

|

View |

Yes |

Yes |

Yes |

|

Add Signature |

Yes |

Yes |

Yes |

|

Report Lists |

Yes |

Yes |

Yes |

|

Report Lists |

Operator |

Manager |

Admin. |

|

Designer |

|

Yes |

Yes |

|

New Report |

Yes |

Yes |

Yes |

|

Delete |

Yes |

Yes |

Yes |

|

|

Yes |

Yes |

Yes |

|

Make PDF |

Yes |

Yes |

Yes |

|

|

Yes |

Yes |

Yes |

|

Copy |

Yes |

Yes |

Yes |

|

Report Sections – Add |

Yes |

Yes |

Yes |

|

Report Control |

Yes |

Yes |

Yes |

|

Report Sections – Edit |

Yes |

Yes |

Yes |

|

Report Sections – Delete |

Yes |

Yes |

Yes |

|

Report Sections – Print |

Yes |

Yes |

Yes |

|

Setup |

|

Yes |

Yes |

The 'System Administrator' can control the minimum length of password and ID from this window in the Password Controls frame. The password age limit is only used as a default in the password window.

2.1.3 Changing and reminding Passwords

To change a password, select the Change Password option on the Setup menu and enter your ID and password and you will be able to set up a new password.

To remind an operator of a password the ‘system administrator’ can click on the operators name on the list, the name should appear on the bottom right hand frame. Click on Renew Password and the next time the operator enters his or her ID, TQSoft will automatically force the operator to create a new password.

2.1.4 To De-Activate an Operator

Highlight an operator and press De-Activate. The operator list should be updated to indicate the status.

De-activated operators can be re-activated again.

De-activated operators signatures will still appear as valid signatures.

A de-activated operators ID or password cannot be re-used for another operator.

2.1.5 To Change what an Operator can Do

Highlight an operator and press the buttons just above. Program functions are divided into a number of categories. The checkbox names should match the menu or button names.

2.1.6 To Backup or Move All Operators to another Computer

Simply backup or move the operat3.ini file in the LOGSYS directory. This will transfer all ID's to another computer where signatures can be entered and validated. As a word of caution though, note that if a password is changed on one computer, it will not automatically be changed on another computer. Under no circumstances try to edit this file. If you try then all access to TQSoft will be lost. Because of this it is important to always keep an up to date backup of a good operat3.ini file in case the file is tampered with or corrupted.

2.1.7 Adding Digital Signature to Records

Digital signatures require verification using keys and encryption.

TQSoft requires the use of a password before an ID can be put into a document. Once in a document, TQSoft will not actually print the ID (it is always encrypted), but instead prints the name associated with the ID.

Use the Add Signature button in Test Notes, Data Listing preview, Test Report preview, and calibration report preview. TQSoft allows two signatures to be added to each report. Signatures cannot be deleted.

Each time TQSoft prints a document with a digital signature indication, it will validate the ID in the document against its database of ID's (in the operat3.ini file). If the ID is confirmed then TQSoft prints VALID ESIG where the user would normally sign (see section Calibration Records Viewing Signing and Printing)

For the reason just mentioned, if test records are moved or sent to another PC running another installation of TQSoft, to validate the signatures the operat3.ini file needs to be present on that PC too. The way around this is to convert reports to PDF format and distribute these. (VALID ESIG will always appear on them on another PC).

TQSoft

automatically allows a signature to be added to calibration reports and test

records at the end of a calibration and test, with the window shown below. Note

that TQSoft defaults to show the currently logged in operator as the signatory,

but any person in the operator list can sign by pressing Esc, and entering his or her ID. (However, any person signing will

have logged in at least once in the past in order to set up their ID and

password.)

2.1.8 Adding Electronic Signatures

An operator's signature in digital graphic form can be considered the equivalent of a hand written signature. However the person concerned must sign an agreement that confirms that that this is so and that he or she agrees and understands.

The security window Add Signature tab allows the Administrator to select a signature graphic file for each user. The graphic should be in JPG format and it should be approximately length = 3 x height. Otherwise the graphic will look distorted when appearing in documents.

The electronic signatures must be imported into TQExpress templates and Word documents by configuring the templates to import the graphic. See the TQExpress manual sections for Data Source Special Functions for guidance.

2.1.8 Password Controls

Using the password controls provided in the Security window, the system administrator may:

control the minimum length users are allowed for new passwords and ID's.

set a default value for the age limit of new passwords.

Set the time allowed for inactivity. If TQSoft does not detect any button presses or key presses for this time, the password window will appear, and no other operations will be allowed until the password, or a new ID and password are correctly entered. Entering any value up to 00:00:11 will disable this feature.

New users will not be allowed to setup their ID and password in the inactivity timeout window for obvious security reasons.

2.2 Selecting a Logger

See Appendixes for further information about

particular loggers that can be used with TQSoft. Many loggers need extra

support software to be installed. See also section 2.10 for setting up a

database record for the logger you will select here.

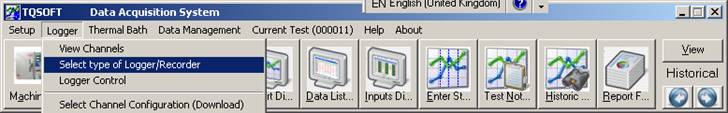

Choose the drop down menu Logger and then ‘Select type of logger’.

Select the correct

logger, baud rate and port. Most loggers have default settings that should

work. For other loggers you may need to look at the documentation to find the

required values. The drop down list on the comms port selection will indicate

which ports are available on the PC. It also lists which ports are used by the

thermal bath and reference probe hardware.

Select the correct

logger, baud rate and port. Most loggers have default settings that should

work. For other loggers you may need to look at the documentation to find the

required values. The drop down list on the comms port selection will indicate

which ports are available on the PC. It also lists which ports are used by the

thermal bath and reference probe hardware.

If you see an error report when pressing OK you need to try another selection. If you get no error report, then check that TQSOFT is communicating with the logger properly by using the Inputs Display button on the main toolbar. The values should be updating regularly, and you should be able to hear the logger scanning its inputs.

Use the logger control menu option on the logger dropdown menu to access a window individual to each logger.

2.3 Channel Configuration

Before doing any calibration, it is important to set up the channel configuration. The channel configuration is fundamental to the system. It describes what each channel on the logger is. It contains information about the type of hardware connected to the channel, the colour of the channel on the chart, and the format of the digital data collected from the channel.

TQSOFT allows you to set multiple channel configuration files. If you intend to use just one logger then you probably need use only one channel configuration file. If you wish to use more that one logger then you will certainly need a separate channel configuration file for each logger.

On the Setup drop down menu choose Edit Channel Configuration. You should see the window shown below.

Consult the logger manufacturer for the correct channel types. Important note: Please bear in mind that Editing the Channel Configuration files does not mean that your edits are used straight away. When leaving the edit widow, you have the option of downloading the file you have just edited, or you can use the option ‘Select Channel Configuration’ on the Logger drop down menu.

The File name

refers to the name of the channel configuration file, and can be found in the

installed LOGSYS directory.

The File name

refers to the name of the channel configuration file, and can be found in the

installed LOGSYS directory.

The channel number goes from zero to the maximum number of channels available in TQSOFT and is shown here only to help you know what channel you are editing. Note that using the > and < buttons will allow you to access more channels than are supported by your logger. You need only set up those channels supported, and can ignore the rest.

The Label is a brief 6 character name that is used in the values display window and digital listing to identify the channels. Entering a label ‘TREF’ will allow a channel value to be used as a reference in a calibration. See next section to reference channels in TQExpress.

The fast measurement option only applies to the Anville logger. Please consult the Anville documentation for the meaning of this option

Channel type describes what sort of hardware you are using to measure temperature and pressure. If you select a 100mV thermocouple then you should normally enter 1 decimal place, if 10mV then you should enter 2 decimal places.

Anville: Supports all selections except +/- 5V

Fluke: Any thermocouple selected is sent as "TEMP,T" otherwise "VDC,AUTO" is sent.

Yokogawa 1800: The

The Units are selectable. Custom units can also be typed in. See Appendix G.

The Decimal places determines where TQSOFT places the decimal point in each of the channels values. This will normally be 1 or 2 for temperatures, 3 for bar pressure or 0 for mb pressure. The decimal places will normally depend on the Probe Type selection.

Chart colour determines the colour of the channel trace on a colour screen and colour printer. Either select from 16 basic colours, or select from a palette.

The location of the sensor can be entered here. The locations are be printed in the digital listing report, the chart trace ID panel, and in the sensor locations report in TQEXPRESS. Note that sensor locations entered here do not have priority over locations entered into the probe location column in the Test Specification. The location entered here will only be used if no location is entered into the Test Specification. See next section too.

2.3.1 Identifying Channels for Analysis and TQEXPRESS.

The channel locations are now held in the Test Specification Probes tab. If you are using TQEXPRESS to analyse your data files then you can use either the channel name, or location, to help TQEXPRESS automatically identify the number of certain sensors, as shown blow. The letter combinations are as follows (in bold) and case independent;

Chamber Pressure Sensor PRES

Chamber Spray Pressure Sensor SPRAY

Drain/Vent Sensor DISCHARGE or SUMP or DRAIN or VENT or FREE or CHAMBER.

Chamber Free Space Sensor FREE

Test Pack Sensor PACK or TEST or LOAD or CENTRE

Top Pack Sensor (Top Sheet) TOP

Bottom Pack Sensor BOTTOM

Water Reservoir Sensor WATER

or RESEV

To exclude from sterilization analysis. N/A (in label), NOT USED (in location), WATER, RESEV, DRYER, CJC.

Be careful not to include the same letter combination in two sensor names or locations. If you do the program will pick up the first sensor that qualifies.

Note that Water Reservoir sensor is excluded from the automatic sterilization analysis. I-Calcs are not affected by these settings.

2.3.2 Switching Channels Off

In the channel configuration on the channel type list you will see an option called OFF. Selecting this will ensure that the Inputs Display window always shows OFF, and that the channel cannot be selected for a calibration.

2.4 Calibration Overview

Most users will use just one calibration file, since they will re-calibrate sensors before each testing session. For each set of sensors that you use you can set up a calibration file that contains adjustments for each channel as well as the most recent calibration and calibration checking details.

Calibration and calibration checking of thermocouples will normally be performed by comparison with a traceable reference value using the calibration procedure in TQSoft covered in the next section. Calibration of thermocouples in TQSoft is more accurately termed calibration adjustment, since the true calibration of thermocouple voltage into Celsius is performed in the logger using standard tables based on pure metals.

Calibration of other sensors such as pressure transducers is known as ‘scaling’. Some loggers allow scaling range to be entered directly in the TQSoft channel configuration window. The loggers that allow this can be programmed with the scale range information. (This is done automatically by TQSoft when downloading channel configuration). Loggers that allow scaling do not need transducers to be calibrated manually as described in the next paragraph.

Scaling can also be done using the Manual Calibration Adjust option on the Logger menu to enter a measurement value in, for example, volts, and an actual value in scaled units. The TQSoft calibration procedure can also be used but is effectively the same as entering measured and scaled values at two points either end of the transducer range. As with temperature a scaled reference value is required, but must be manually input.

This version of TQSoft supports up to 16 calibration points manually input, but the automatic calibration will still calibrate a maximum of two setpoints.

To get to the calibration file window select Calibration Files from the Logger drop down menu. Each calibration file is represented by the thermal bath icon. Click on one to see the channel settings.

Channel settings (label, type, units) are taken from the current channel configuration until a channel is manually calibrated or a test is run, when the settings are fixed. If a TQSoft calibration procedure is performed channel settings are always renewed from the current channel configuration selected.

It is important that Test Specifications have compatible channel configuration files and calibration files. For example if a channel configuration has channel 16 set as a pressure channel, but user selects a calibration file with a thermocouple adjustment stored at channel 16. This is normally avoided by the good practice of calibrating sensors using the correct calibration file before testing.

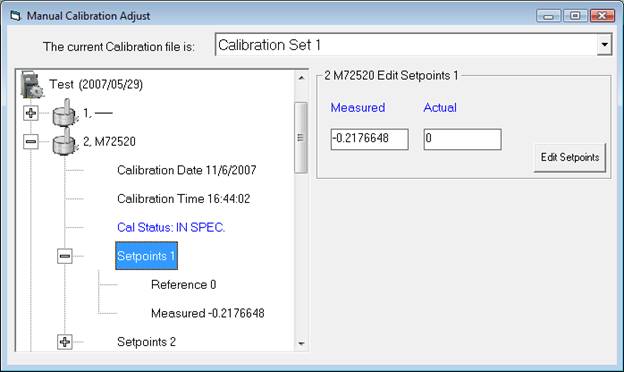

Setpoints can be added to a channel by using the Manual Calibration Adjust option on the Logger menu, and clicking on a channel icon. Setpoints can be edited by using the Manual Calibration Adjust option, and clicking on a setpoint.

2.4.1 Sensor Usage

Sensor usage can be accessed in the Calibration Files option on the Logger menu.

If the Calibration Files window shows an entry called Usage Criteria, TQSoft can be used to monitor and alert usage of sensors. Click on the range(s) to see usage limits set for specific temperature ranges. Ranges can be customized in a file called UC.INI.

Usage of each sensor can be seen by double clicking on a calibration file and then on a channel. An entry called Usage may appear and will show the number of tests and time of use.

When sensors are used outside limits set alarms will appear when logging is started.

A sensor uses a range according to the maximum temperature that it has been used at. Usage can be reset here with the Reset button.

2.5 Calibration Set Up.

To

perform a calibration you should have set up a calibration file first, however

the program is installed with an example calibration file that you can use. To

start a calibration select Calibration

from the Logger drop down menu.

To

perform a calibration you should have set up a calibration file first, however

the program is installed with an example calibration file that you can use. To

start a calibration select Calibration

from the Logger drop down menu.

This is very

important. The calibration results (factors and offsets) will be stored in

this file and will overwrite existing values. Make sure you have selected the correct calibration file.![]()

The calibration details form shown here will normally be filled in automatically for you. The operator name comes from the password that you entered. The date and time come from the PC clock. The Job Ref is the job reference last entered either here or in the start test window.

The calibration file selection is most important. The results will be stored in this file and will overwrite existing values. Make sure you have selected the correct calibration file.

During calibration TQSOFT will use the most recently used Channel Configuration file. If you are using multiple channel configuration files or if you have just started using TQSOFT you should check that you have the correct one selected by pressing Cancel and using the select Channel Configuration option on the Logger menu.

Next you will be required to select what channels you want to calibrate. The program checks your selections and alerts if your selections are not viable. There are some rules that must be followed. Channels configured as thermocouples cannot be calibrated together with a channel configured for a pressure transducer. With Sterimizer, multiple temperature calibrations have to be selected contiguously from the start of a temperature ‘block’.

.The calibration setup window shown here should appear.

Setpoints

The Low Point must be at least 10 degrees below the

You have the option of doing the

Options

The automatic check box will only be

enabled it you have a Thermal Bath set up and TQSOFT has successfully

communicated with it before this window appeared. With the automatic option

selected TQSOFT will itself program the bath setpoint temperatures, and monitor

stability requirements, and will complete the whole calibration without the

need for operator input.

Configuring a channel with label ‘TREF’ will enable the calibration to

use the channel value as a reference.

Stability and Reporting

With a non-automatic calibration,

you do not need to use the stability criteria, because you can instruct TQSOFT

to calibrate when the values are seen to be stable enough. However, even in

non-automatic mode, TQSOFT will display a stability countdown, and you can use

the countdown as an accurate judge of the quality of stability achieved.

ALL probes selected for calibration

must achieve the stability criteria, here for example it is 0.2 degrees for 3

minutes. If these are left blank, then TQSOFT does not display a stability

countdown.

The allowed deviation from Reference

is applied as soon as the calibration is calculated. If the difference between

any uncalibrated probe value, and the reference value, is greater than this

figure, then the probe is labelled as a BAD probe in the calibration report. The allowed

deviation is applied at Low and High points.

The reference stability criteria is

simply the biggest drift allowed for the reference value in one minute. A

countdown is provided for this too, and is reset as soon as the reference value

drifts too far. If the entered setpoints are being used as reference values

then this criteria is irrelevant since the setpoints do not drift!

The report duration and interval are

used to generate a (post calibration) report on the calibrated values after

High and Low point calibrations. Leave these boxes blank to skip out the post

calibration reporting altogether. The report

max. deviation allowed is a limit on the difference between each channels’

value and the reference value during the report interval. If the difference is

exceeded the channel will have a FAIL notice appear in the calibration report

results section.

When OK is pressed the stability

monitoring window should appear.

2.5.1 Waiting for Stability

![]()

2.5.2 The

Post Calibration Report Window

If a report time and report interval have been set up, the report window will appear after any setpoint calibration.

2.5.3 Calibration Reports

At the completion of calibration TQSoft shows the calibration records window with the calibration just completed highlighted. See section 4.7 Calibration Reports Viewing and Printing for further information. The calibration report is also automatically archived if the archiving option is configured.

Uncertainty

The calibration report contains 2 lines at the end of the report after adjustment section labelled standard uncertainty and combined uncertainty.

Standard uncertainty is a calculation on

each deviation listed in the section and is estimated standard deviation / square root of

number of samples.

Combined uncertainty is the square root of the sum of the squares of

the uncertainties of the logger and reference, and above mentioned

deviations.

2.5.4 Manual Calibration

Adjust

The manual calibration adjust window on the Logger menu allows the calibration setpoint measured and actual values to be manually adjusted. See the Calibration Files section above for more details, and for details of how to add more than 2 setpoints.

All changes are also logged in the audit trail.

2.5.5

Advanced Calibration.

The Advanced calibration procedure can be used much like the standard calibration window outlined above for automatic or manual calibrations or calibration checks. The additional advanced features are.

Use the Name box to enter a name, and use the Save dropdown menu option to save the complete window setup for retrieval later.

Build a list of your calibration setups which can be accessed with the Name dropdown list, or the menu item Select Setup.

Manage calibration setups. Add new ones by changing the Name and using Save Setup. Delete with menu item Delete.

Calibrate or check up to 10 setpoints.

Perform calibrations and checks independently of other TQSoft tasks.

2.5.6

Advanced Calibration for Remote

Loggers.

The Advanced Calibration Procedure is particularly useful for calibrating and checking remote loggers.

For both procedures below, use a calibration file that has logger ID’s setup correctly.

2.5.6.1

Manual Setpoint Calibration Procedure

- All figures are examples only…

- Program loggers with a test specification

settings interval 5 seconds, log for 4 hours (for example).

- Put loggers into oil bath and change

setpoint to -50.

- Wait for stability and note reference temperature.

- Repeat for all setpoints.

- Remove loggers and download all loggers

data into a Test Record. Be sure not to apply any calibration to the

downloaded data.

- Go the Advanced

Calibration and enter setpoints from reference temperatures noted

earlier.

- Tick the Cal on data File option and select the test record.

- Press Proceed

and wait for stability, use the speed slider to progress calibration

faster or slower. At stability press Proceed

for each setpoint.

- All figures are examples only…

- Program loggers with a test specification settings interval 5 seconds, to log for 4 hours (for example)

- Connect temperature reference sensor to TQSoft and configure a channel configuration to report the reference temperature. Channel chosen must have label TREF.

- Configure a test specification to log just 1 channel (the reference channel) at interval 5 seconds. Must use 24 hour times option.

- Switch to Simulation logger in Select Type of Logger, check Inputs Display for TREF value display, and Start logging the reference temperature in TQSoft.

- If reference is connected to TQSoft.

- Go

into Advanced Calibration and

set for calibration check.

- Enter the calibration (or check) points required, limits are not required.

- Set the reference stability criteria and report duration and interval.

- Click on Automatic.

- Put logger(s) into the bath and start the calibration check.

- The process should proceed automatically.

- At complete the calibration check report is not yet valid (it does not contain the logger data! Loggers now have the data in memory)

- If reference is not connected to TQSoft…..

- Put loggers into oil bath and change setpoint to -50.

- Wait for stability.

- Repeat for all setpoints.

- Stop logging and switch back to battery loggers in Select Type of Logger.

- Remove loggers and download all loggers data into a test record. Must use the 24 hour times option.

- Merge the logger data with reference temperature data. Tick the adjust for start times checkbox.

- Check the merged data on the chart. If necessary use the Crop option on the Current Test menu to ensure that just the programmed stability points are shown on the chart.

- Go to Advanced Calibration and (if required) enter calibration (or check) points.

- Enter stability criteria for the data.

- Tick the Cal on data File option and select the Merged test record.

- Select the Automatic tick box.

- Press Proceed and wait for stability, use the speed slider to progress calibration faster or slower.

2.5.5

Calibration Measurement Adjustments

When data is being collected from the logger,

and Calibration Active setting is set ON, measurements will be

adjusted by the software before display and storage.

The corrections can be seen in the Inputs

Display window by holding the mouse over the measurement values. The sensor

adjustment and logger adjustment will be displayed. Logger adjustment is

normally only used by TQAero.

The process used is as follows:

- If the

measurement lies between 2 setpoints, a ‘straight line’ (mx + b) fit

is applied to the measurement using the setpoints either side of the

measurement.

- If the

setpoint lies above the highest setpoint, or below the lowest setpoint,

only an offset will be applied to the measurement.

2.6 Test Specifications

Test Specifications should be setup carefully with full regulatory guidelines in mind before on site testing.

Test Specification files are fundamental to TQSOFT. They contain most of the information required to record a test. Some information, such as the Chamber being tested, cannot be known until just before logging. Test specification files should be set up and tested before getting to site, and can then be re-used.

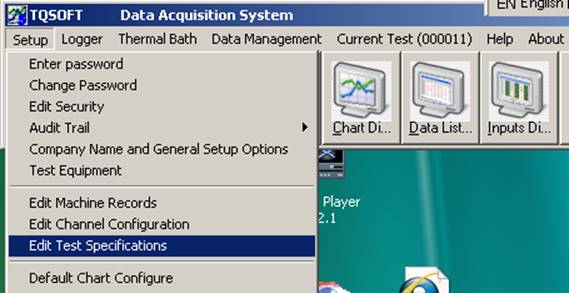

To access test specifications choose Edit Test Specifications from the Setup dropdown menu.

The window will look like the one shown

below, but if you are using certain loggers/recorders there will be an extra

section for parameters specific to each type of logger. Information on the

logger specific parameters can be obtained from the technical documentation for

the logger. See section Logger Specific Specifications for more details.

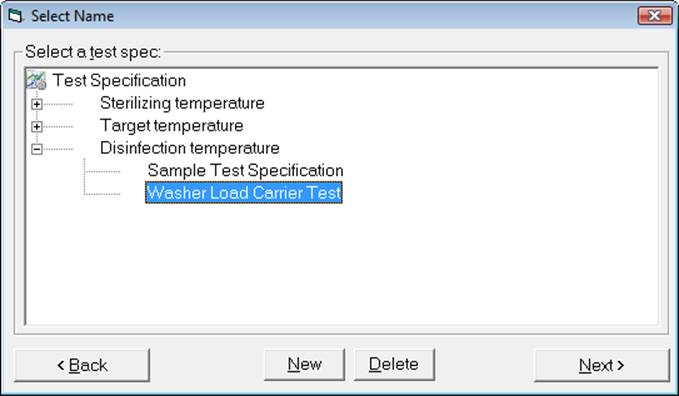

The select

Test Specification name window will appear. This allows Test Specifications

to be managed using the buttons.

2.6.1

General Settings

Name is used to ID the test specification and in the identification of chart and data listing reports.

Temperature Units and Pressure Units are included here so that a test record ‘knows’ which units it is specified in, independent of the TQSOFT installation being used to view the record. Note that these settings are independent of the unit selections in the channel configuration file. It is left up to the user to check the consistency of unit selections. The saturation calculations will use the units selected here.

The scan interval is used to set the minimum scan rate for the test. The rate will be constant throughout the test, but stages can be configured to display data at different intervals for a digital report. If the scan interval is left blank, TQSoft logs scans as quick at the logger will allow.

Estimated Test duration is used by battery loggers to limit the data collection. For other loggers its used only to size the chart for real time monitoring. It is important to get this right of you wish to use the real time chart monitoring system. Note that in version 3 the format has changed to dd:hh:mm to allow much longer chart monitoring.

Version and date of revision is a means of tracking modifications to test specifications.

The calibration file specifies which set of calibration values will be activated and used when the test is started. The small button to the right of the selector will show the manual calibration adjust window with the correct file expanded.

The channel configuration file is the channel configuration that will be loaded and used once the test is started. This is clearly of great importance, and depending on the logger used, the logger may automatically be updated with the specified channel configuration. See the appendices for individual logger functionality. Select the channel configuration file before selecting probes. The small button to the right of the selector will show the channel configuration window with the correct file shown.

The Measurement Rate panel only appears for Fluke Hydra III and Validator. It allows the measurement rate to be controlled for each test. It will limit the scan interval. For Fluke if scan interval is too small for measurement rate, software will scan as quickly as possible but rate that will be achieved is not shown here.

Sterilising/Disinfection/Target temperature

Will allow default limits to be set in the I-Calcs tab based on the sterilization or disinfection temperature. The I-Calcs will draw lines and shaded areas on the chart, and colour data on the data listing. The default I-Calcs are:

·

Specified Temperature Chart

Shaded Area.

This draws a shaded box on the chart between lower and upper temperatures specified. It also triggers use of legacy limits which make Data List temperatures blue above lower temperature, red above upper temperature from Cycle Start to End. To remove this legacy colouring either delete or rename this I-Calc.

·

Specified Temperature

This will draw a line on the chart at specified temperature and make temperatures above specified temperature red on the Data List from Cycle Start to End.

·

Specified Temperature upper

limit

This will draw a line on the chart at specified temperature plus 3, and make temperatures above specified temperature plus 3 red on the Data List from Cycle Start to End.

Will also be used by the Stage Analysis to automatically insert the Start and End stages.

It will also be used by the TQEXPRESS analysis engine to trigger the sterilization/disinfection analysis.

It may also control the time at temperature indicators in the Status window, provided that the lethality tab option Use these settings for time at temperature calculation is OFF.

Adjustment of this temperature will also allow equal adjustment of I-Calc limit values which is useful for a large set of I-Calcs. Deviation I-Calcs and non-temperature I-Calcs are not auto adjusted. Don’t use auto adjustment if you have other temperature I-Calcs that are not related to this temperature value.

The Stage Analysis option forces TQSoft to insert the Equilibration Start, Sterilisation Start and End into a test automatically as logging progresses.

A hysteresis of 0.25 degrees is allowed.

With this option checked, TQSoft will display a hold time message 20 seconds after the end of the hold time. The message will indicate the hold time.

If this option is not checked, and the stages are added manually, the analysis will use the times of the stages inserted for TQExpress import calculations.

The stage names can be customized by editing the file stages.lab in the LOGSYS directory. If you want to change the name Sterilisation Start it is best to move it to the top of the list, since if TQSoft cannot match Sterilisation Start, it will use first stage with CODE 13 in the list. You can delete any stages that are not applicable.

The Use 24 hour clock option controls the format of time in the test record. If checked, time will be stored as actual time of day, if unchecked time will be stored as time offset from the start of the test.

The button with Data List icon is used to control some format options for the Data Listing. When the Test Specification is created the Default Data Listing Configuration (Setup menu) is used. This can then be modified to suit.

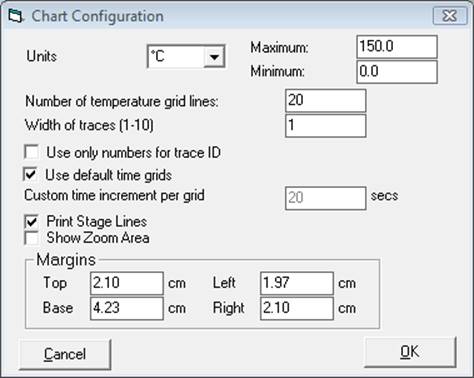

The button with Chart icon is used to control some format options for the Chart. When the Test Specification is created the Default Chart Configuration (Setup menu) is used. This can then be modified to suit.

The auto stop logging after allows you to automatically switch off logging a set time after a

test has started. Having

this checked allows the continuous

monitoring check box to be used.

This will have the effect that TQSoft will automatically re-start logging with

the next incremental test number available.

Having continuous monitoring checked allows the start new file at midnight option to be used. This will have the effect of automatically starting a new logging file when midnight passes. Set auto stop logging after to at least 00:12:00 (dd:hh:mm). Please note that this is 12 hours. Setting auto stop logging after to, for example, 02:00:00 (dd:hh:mm), which is 2 days will then force a new file to be generated every second midnight.

Log off channel and log off temperature can be used to switch off logging when a specified channel has exceeded and then drops below the specified value. Enter “90” or to wait for all selected temperature channels to drop below the specified value.

Limit lines on the chart can now be setup using the Chart Line type of I-Calc. Limits lines can be created automatically when initially entering (into a blank text box) a Sterilization or Disinfection temperature and then pressing Enter. See section 2.6.6.2 What happened to Version 2 Limits?

2.6.2 Calculations

This section of the Test Specification allows calculated channels included in Chart and Data Listing as extra traces or extra columns of data. These are different from the more complex I-calcs described later.

Calculations can be included in TQSoft reports by setting them up to appear by default here.

These calculations will not include probes that have the following references in the probes tab location settings....

"NOT

USED"

"REFERENCE

CHECK"

"WATER"

"DRYER"

"RESEV"

"FREE"

"CJC"

The saturation calculations must be set up here by selecting a channel to base the calculation on, and selecting the units to use in the general section (see above). The saturation calculations are based on formulae quoted in ‘The International Association for the Properties of Water and Steam’ 1997. They can be validated using the option View Saturated Steam Table on the Setup menu.

If you change the channel configuration file selection in the general settings, then the saturation channel selections are automatically blanked by TQSoft.

2.6.3 Lethality

D-Value is time required at temperature T to reduce a specific microbial population by 90%.

Z-Value is the number of degrees of temperature change necessary to change D-Value by a factor of 10.

D-Value and Z-value are

not calculated by software, they are properties determined by labs.

F(0) is a

measure of kill at (minutes at Base

temperature 121.1C) and requires a formula to calculate when temperature is

not exactly 121.1C

A(0) is a

measure of kill at (seconds/minutes at Base

temperature 80C) and requires a formula to calculate when temperature is

not exactly 80C

User has to input the Base

temperature and Z-Value parameters into TQSoft so formula will work correctly.

F(0) and A(0) are 2

lethality calculations, TQSoft can show all lethality calculations in real

time.

At end of a

qualification user can see lethality’s and can compare with the known D-Value.

TQSoft does not need to

consider D-Value, user decides the lethality they want to achieve, based on the

D-Value, and can input that in TQSoft as a target that should be achieved.

The F(0), A(0) option can be used to simplify the frame and insert standard values for these calculations.

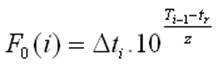

The Z value and Base temperature (tr) are both used for the lethality calculation

Basic Formula……If successive temperatures T(i) = T(i-1)

Enhanced Formula….If successive temperatures T(i) <> T(i-1)

If base temperature is left blank, lethality calculations are switched off.

If Enhanced Lethality Formula is not checked the basic formula is used even if T(i) <> T(i-1). This is the standard method. The enhanced formula yields better results for heat up and cool down phases when temperatures are rapidly changing between readings.

Full lethality in data Listing is used by the listing report as a default. The F calculations can be switched on and off from the digital listing window itself.

Minimum lethality is a calculation that can be included by default just like the calculations section.

Minimum Instant lethality is a calculation that can be included by default just like the calculations section. If this is ticked,and Minimum lethality is not ticked, the Data List will show instant values in each row instead of the default accumulation.

Chart to show lethality axis is a setting that will override the default pressure axis on the right hand side of the chart.

Select

Probes allows the lethality calculations to be

performed only on certain probes.

Start lethality on is a means of only calculating the lethality above a certain temperature for selected channels. The stage selector will trigger the lethality calculations when the stage is inserted into the test. If both are selected the condition is AND.

End lethality on allows the lethality calculations to be stopped at a particular stage.

Temperature/Pressure Correlation limit allows user to setup a limit which will apply to all channels selected for this lethality calculation. The saturated pressure equivalent for each channel is compared to the pressure value of the channel specified on the Calculations tab. If any temperature is outside the limit, the lethality calculation is reset or suspended according to the Reset lethality if correlation over limit check box. The correlations can be viewed in real time in the Status Window.

Use these settings for time at temperature calculations will make the time at temperature for each channel accumulate whenever the lethality is accumulating. If not set the time at temperature will depend on the Sterilization temperature on the General tab. These time at temperature calculations are ‘in-built’ and are separate from the Show time accumulation option in the I-Calc Actions tab. The I-Calcs are in some ways more flexible, but cannot be configured to correlate with the saturated steam pressure.

Please note that all lethality calculations are redone when user makes a historic adjustment to the lethality settings tab.

.

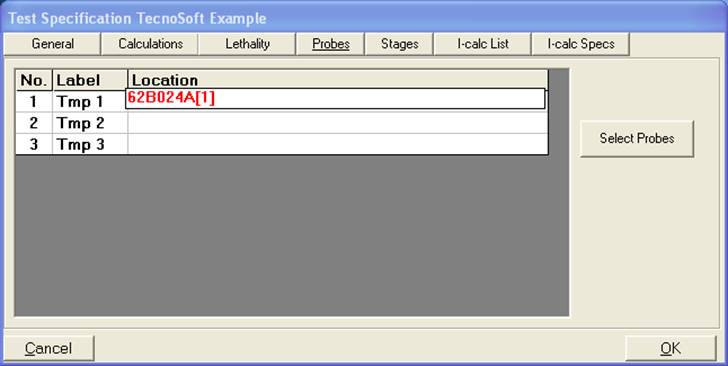

2.6.4 Selecting which Probes to log and probe Groups

This section lists the channel labels and locations of the probes selected to log for this test specification. The names displayed in the list depend on the channel configuration file selected for this test specification.

The location column is editable by clicking on a location box, or pressing SPACE key. Edited text is shown in red, then press ENTER when edit is complete. Up to 60 characters can be entered but only 40 can be displayed on the Test Setup report.

Note that TMI loggers have a special use for location. See Appendix M.

To assign a probe to a group use the group number anywhere in the location text in {} brackets. For example to assign Channel 6 to group 1 add {1} anywhere in the location. See the examples in the picture above.

Groups are used for I-Calcs and the group number can be used instead of specifying each channel. This is very useful when there are large numbers of I-Calcs and a change must be made to the channel assignments.

Groups can also now be selected in charts, data list and report lists.

Additionally, each group can be assigned to a different chamber. This allows user to have groups of sensors in different chambers for simultaneous testing, saving much test time. The selected chamber details will appear in the group reports.

2.6.5 Setting up a Stage List for a Test Specification.

The stages tab is optional, and can be used to set up a stage list for each test. This is then used when the test is running to aid the operator entering stage times as they occur. However, the stages and times can also easily be entered historically, once the test is finished.

![]()

The window for setting up a stage list for a specification is

shown below, and is accessed by pressing the Stages button on the Stages

tab.

The list

on the right is the set of stages set up for the test specification. An

interval is used to produce a digital summary of the data, and is configurable

on a stage by stage basis. You can change the interval either on the list of

all stages or on the test list on the right with either interval button as

shown.

2.6.6 ICALCS

2.6.6.1 Introduction & I-Calc Wizard

This version of TQSoft ships with an I-Calc Wizard function. This is recommended as the best way to become familiar with what is possible with I-Calcs. To access the Wizard, go to the I-Calc List tab of a Test Specification, and double click on one of the I-Calcs, or if there are none press New button then double click on the New item.

The wizard will display notes on each of the I-Calc types and options available, changes to an I-Calc will not be saved until the end of the Wizard and the back button can be used at any time to abandon changes.

If the next button will not advance, and switched curser focus to an empty box, the window requires further input to proceed.

The old I-Calc configuration window is still under the I-Calc Specs tab in the Test Specification window.

I-Calcs are not the same as the derived channel calculations on the calculations tab. I-calc, short for interval calculations, allow the user to set up calculations on selectable groups of channels, to be performed over a period of time. The period of time is specified by using the stages in the test stage list. Calculation results can be included as messages in the Data Listing, and are accessible by TQEXPRESS forms. Furthermore, limits can be setup for I-calcs which then allow a number of actions to be performed if a limit is breached. This includes the ability to insert a new stage into a test record which can in turn be used to start or stop other I-calcs.

Up to 256 I-Calcs can now be created in a test Specification.

I-calc results are all generated automatically in real time and so can be used by a continuous monitoring application to compare each test with specifications generated from a validation, and alert any deviations.

I-calcs can also be constructed and applied historically, allowing historic records to be processed, and also allowing I-calcs to be designed and then tested instantly.

To help setting up I-Calcs we have provided discussion of an example EN554 Test Specification below which should be more helpful than considering each software option in isolation. It is hoped that the engineer will quickly appreciate the functionality once the worked examples are studied.

ICALCS and Limits were designed for the following application areas. To understand whether and how to use them it is essential to identify the area concerned.

In order to set up validation calculations required or recommended by the various regulatory organizations or in house SOP, with optional limits that can highlight failed calculations and the tests that they occur in. Note that this will include interval calculations as well as the TQEXPRESS analysis engine calculations that are performed at the end of a test.

In order to set up limits based on channel values or calculations that can be used to insert standard or custom stages into a test. (See 2.11.1)

In order to set up calculations with limits that can be used for long term automatic monitoring of sterilization processes. In this case there are several other functions added in version 3 that will be required.

In order to set up limits that TQSoft monitors for long term continuous monitoring of facilities and plant. In this case there are several other functions added in version 3 that will be required.

2.6.6.2 The I-Calc list

The I-Calc list allows I-Calcs to be generated and managed quickly. For example, when you have completed and tested one called ‘Max 1’, calculating the max of channel 1 during sterilization. Now highlight Max 1 and press the new button and answer duplicate. A new I-Calc should appear called Max 2, with the channel selection automatically at channel 2. This way lists can be quickly generated.

Groups of I-Calcs can also be selected and by editing one of the group the channel selection, start stage and end stage of the entire group can be amended in one operation.

Groups of I-Calcs can also be deleted and copied to another test specification.

During initial use of TQSoft It will often be the case that engineers will log a test, and then add or modify I-Calcs of the test, and re-analyse until calculations are setup correctly. When modifying I-Calcs historically like this, modifications and editions can be sent quickly to the original test specification (that will be used for new tests) using the Send function on right click of an I-Calc.

2.6.6.3 Creating a New I-Calc

To create an I-Calc press the New button. If an existing I-Calc is highlighted, it will be duplicated as a new one. If existing I-Calc was not highlighted, the I-calc tab should look like this;

These are the default entries. Now it is a matter of deciding which sort of I-Calc to select from the Type selection list at the top left.

If a Test Specification is saved with I-Calcs with duplicate names, a (2) is appended to the second name.

2.6.6.4 Deciding Which Type of I-calc to Use

It is important to have a clear idea of the calculation that is required. To illustrate the potential confusion consider the diagram below;

The Max and Min gets the result maximum – minimum probe value for whole interval.

The Max Deviation gets the maximum difference between probes at any one point in time for the whole interval.

The difference between Max and Min of Maxs gives the TQSoft calculation (Max-Min) of Maxs.

In practice the results of calculations 1,2,3 could be very different as you can see here;

In practice, to get the maximum fluctuation of each probe individually, we need the Max-Min result shown below, over an interval.

There is also the crucial distinction between continuous monitoring and interval monitoring. The simplest case is Max probe value. Putting a limit on a Max calculation for an interval will get a simple report of the result, placed where the Max occurred, and the result will either pass or fail the limit values.

The same limits applied with continuous monitoring will cause an event to trigger whenever the Max value goes above an upper limit, or below a lower limit. A report will appear where the triggers occur, not where the overall Max value occurs. The overall Max value will not be reported.

So Max probe value calculation applied continuously is a completely different concept to Max probe value applied to an interval. The same applies to all the calculations.

Where TQSoft is so powerful is that it allows continuous monitoring to be done during intervals.

In general you will use continuous monitoring of temperature to trigger the insertion of stages such as the sterilization start, equilibration start and lethality start stages, and interval calculations to check the process performance between the inserted stages.

Continuous monitoring can also be used to make I-Calcs appear on chart and data list Use the Test Spec I-Calc action plot calculation on chart/data list. The hide interval probes will hide probes that make up the calculation, but not for the data list.

Another important use of continuous monitoring is calculating humidity based on a dewpoint sensor connected to the measurement unit and located in the chamber. One I-Calc can be setup for each temperature measurement instead of separate humidity sensors. TQSoft uses this formula to calculate humidity:

100 * (Exp((-6096.9385 / (273.15 + dpv)) + 21.2409642

- 0.02711193 * (273.15 + dpv) + 0.00001673952 * (273.15 + dpv) ^ 2 + 2.433502 *

Log(273.15 + dpv))) / (Exp((-6096.9385 / (273.15 + t)) + 21.2409642 -

0.02711193 * (273.15 + t) + 0.00001673952 * (273.15 + t) ^ 2 + 2.433502 *

Log(273.15 + t)))

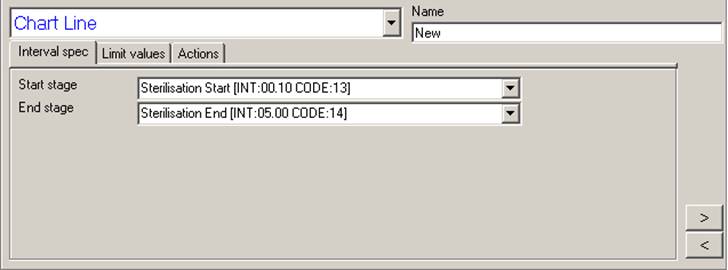

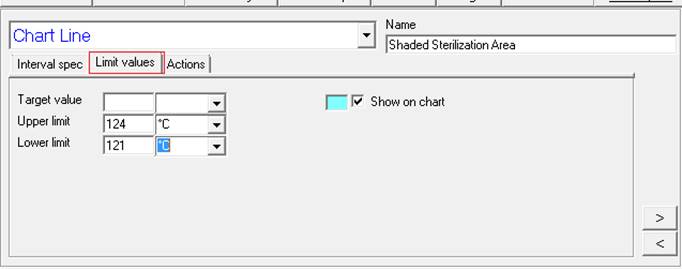

The Chart Line

Use this if you simply want to display a line on the chart, or a shaded area. It can also be used to draw a line between two stages.

Only the upper and lower limit values are drawn on the chart (not target), but the target can be used to draw an upper or lower line based on % from the target. In this case be sure to use % as the units selected for the limit values.

Ensure that the show on chart is checked.

Ensure that correct units are selected.

Enter both upper and lower limits to shade an area.

Stage/Message Insert

Use this if you want to insert a stage message into the Data Listing and chart when a particular event occurs. This might be used to insert a sterilising start stage when the Min Lethality calculation has reached a certain value.

A stage is only inserted on the first event occurrence. If, for example, a minimum temperature is monitored and is triggered, the stage insert will not be triggered again if the temperature subsequently re-triggers.

It is IMPORTANT to ensure that the Start and End stages are selected correctly. These would normally be Cycle Started and the stage that is being inserted. If, for example, a stage such as Sterilization Start is used as the start stage, TQSoft will not look to insert the stage message until after sterilization has started.

If hardware supports Digital IO, the Trigger on Digital Inputs selector can be used to insert a stage when any IO channel changes state. Stage will not be re-inserted if state subsequently changes again.

If hardware supports Digital IO, the Digital Outputs LOW and HIGH selectors can be used to manipulate the digital outputs. Check which input state corresponds to LOW and HIGH with a meter. (The Digital IO window on the logger menu can toggle output state, LOW is checkbox ON, HIGH is checkbox OFF.)

Continuously Monitored Interval

This is the most complex I-calc. Use this to alert and insert alert messages on a continuous basis. It is designed more for facilities monitoring where channels can go out of, and in to specification on a number of occasions.

The start and end stages can be used to limit monitoring to certain periods.

When events re-occur, the actions are re-triggered. This is the main difference from the previous type of I-calc.

A hysteresis can be programmed to prevent frequent spurious triggering around the limit value. The hysteresis values are entered as proper values, NOT offsets. So, for an upper limit of 40 degrees, a hysteresis might be entered as 41 degrees.

Hysteresis can also be entered as a time format hh:mm:ss. In this case the limit will not be checked until this time has elapsed since start of the interval.

If hardware supports Digital IO, the Digital Outputs LOW and HIGH selectors can be used to manipulate the digital outputs. Check which input state corresponds to LOW and HIGH with a meter. (The Digital IO window on the logger menu can toggle output state, LOW is checkbox ON, HIGH is checkbox OFF.) The output state will be reset if the I-Calc limit goes back into specification.

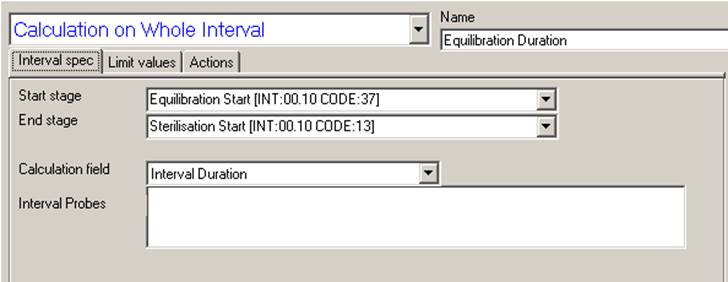

Calculation on Whole Interval

Use this if you want to insert a calculation based on the time between any two stages in the test. The calculation will be performed when the end stage occurs.

Be sure to enter start and end stages correctly, calculation will not appear if either stage does not occur.

This I-calc differs from the Stage/Message insert because the calculation is inserted as a stage AFTER the end stage, NOT when the limit is exceeded.

If the limits are exceeded the stage is displayed in red in the Data Listing, and the highlight test option can be used to turn the test record red in the Historical Test list.

If hardware supports Digital IO, the Digital Outputs LOW and HIGH selectors can be used to manipulate the digital outputs.

Calculation on Whole Test

Is RESERVED FOR FUTURE USE. These HTM2010 calculations are not presently validated and rely on the TQSoft channel configuration containing correct channel identifiers for Drain, Load etc. Moreover there is no ability to specify channel groups or stages for calculations. The calculations are based on the TQEXPRESS analysis engine.

2.6.6.5 The Calculations

Note that all calculations will include the values of the scan of the start stage, but will NOT include the values of the scan of the end stage. The exception to this is if a Time Offset is programmed into the I-Calc, then the values of the end stage scan ARE included.

INTERVAL DURATION

Returns the time elapsed between two stages. So can be used to monitor the period of time a specified condition exists during the test, e.g. time probe X or probes X,Y,Z were in excess of a specified temperature.

Stage Insert on Elapsed Lower Limit Time.

This function will insert specified stage once the time specified has elapsed from the specified start stage.

Maximum Probe value

This function will return the HIGHEST value a sensor or specified group of sensors achieved within a specified period.

Minimum Probe value

This function will return the LOWEST value a sensor or specified group of sensors achieved within a specified period.

Multiple

This calculation displays the maximum value in the data list stage but it stores max, min, average, standard deviation and uncertainty in the Interval Analysis section for import into summary sheets. This does reduce the number of I-Calcs required for some summaries.

Max and Min

This function will monitor the specified max and min limits. Any values outside either limit will cause the I-Calc to insert the specified stage or perform the specified actions. If an upper limit beach is in effect a co-incident lower limit breach will not be reported. If its critical to see both use separate I-Calc for each upper and lower. This I-Calc is useful to signal an overall PASS/FAIL over a furnace stability phase.

Group Fluctuation

This function will return the maximum DIFFERENCE between the HIGHEST and LOWEST values of a sensor or specified group of sensors achieved within a specified period.

Max Single Fluctuation

This function will return the maximum individual sensor DIFFERENCE between the HIGHEST and LOWEST values, from a specified group of sensors within a specified period.

Max Mean Kinetic Temperature (MKT)

This function returns the maximum MKT of a group of probes over the specified period.

Min Mean Kinetic Temperature (MKT)

This function returns the minimum MKT of a group of probes over the specified period.

MAX DEVIATION

This function will return the maximum DIFFERENCE between the HIGHEST and LOWEST values a sensor or specified group of sensors achieved DURING A SINGLE SCAN within a specified period.

MIN DEVIATION

This function will return the minimum DIFFERENCE between the HIGHEST and LOWEST values a sensor or specified group of sensors achieved DURING A SINGLE SCAN within a specified period.

AVERAGE PROBE VALUE

This function will return the AVERAGE value a sensor or specified group of sensors achieved within a specified period.

MAX of MINs

This function will return the HIGHEST value of a specified group of sensors’ MINIMUMs achieved within a specified period

MIN OF MAXs

This function will return the LOWEST value of a specified group of sensors’ MAXIMUMs achieved within a specified period

(MAX-MIN) of MAXs

This function will return the DIFFERENCE between the HIGHEST and LOWEST values of the MAXIMUM values of a specified group of sensors achieved within a specified period.

MAX LETHALITY

This function will return the HIGHEST LETHALITY value a sensor or specified group of sensors achieved within a specified period. The lethality calculation itself MUST be set up correctly separately in the Lethality tab. The channels selected in this calculation must be included in the lethality channels for this calculation to work.

MAX INTERVAL LETHALITY

This function will return the HIGHEST LETHALITY value a sensor or specified group of sensors achieved within a specified period. The lethality calculation itself MUST be set up correctly separately in the Lethality tab except for the specified period. The channels selected in this calculation are also independent from those in the lethality tab.

MIN LETHALITY

This function will return the LOWEST LETHALITY value a sensor or specified group of sensors achieved within a specified period. The lethality calculation itself MUST be set up correctly separately in the Lethality tab. The channels selected in this calculation must be included in the lethality channels for this calculation to work.

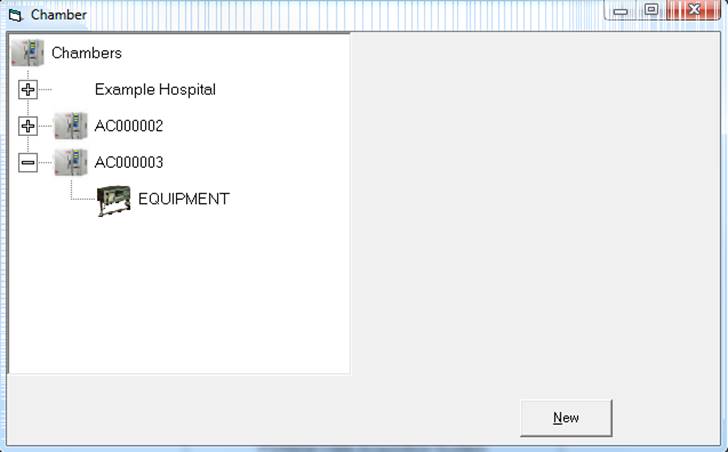

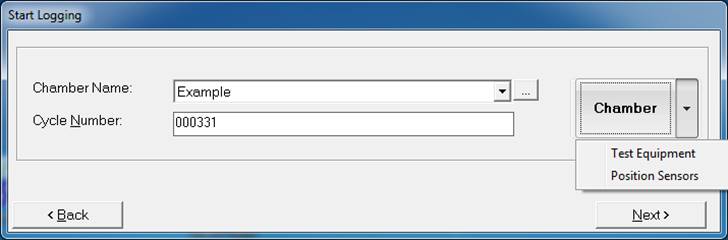

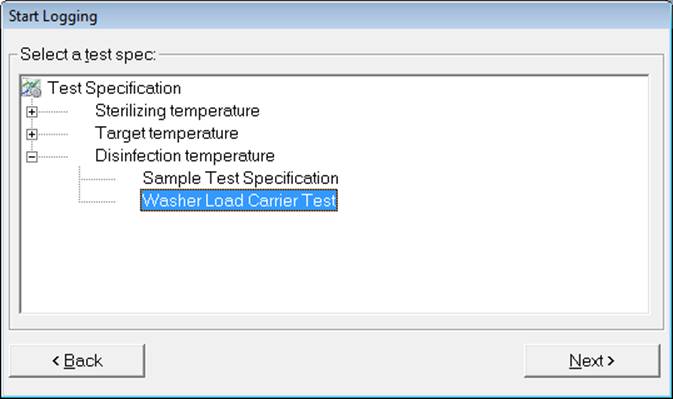

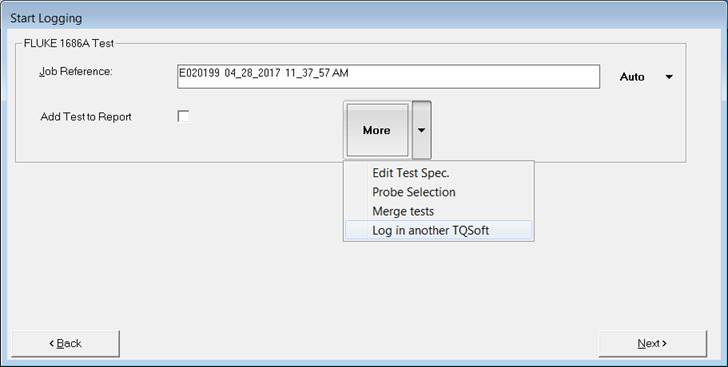

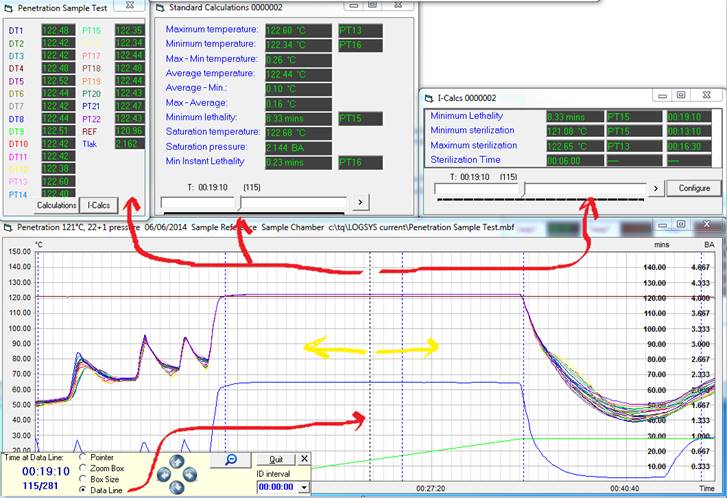

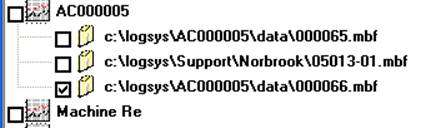

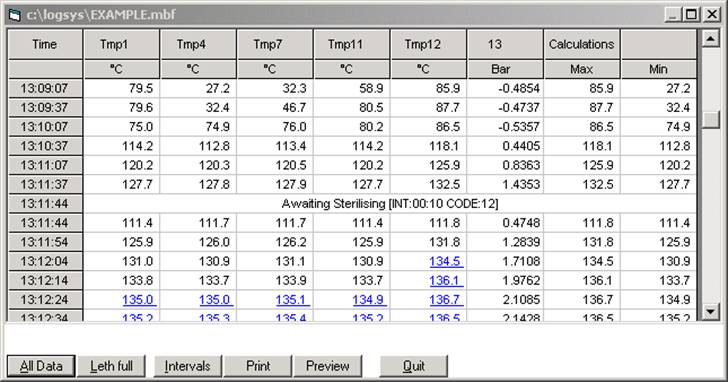

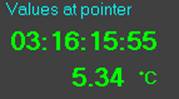

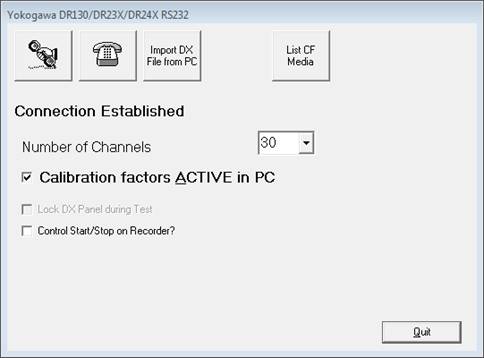

MIN INTERVAL LETHALITY